Mining and Quarry Dust Collectors

There are dangers in the mining and quarry industries that can be fatal if not properly addressed. Fires and explosions can occur if there is a lack of ventilation on sites. And dust-laden air can cause sickness and disease to those working on these sites.

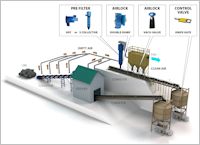

The use of dust collectors in these applications helps remove the dust from the air allowing the air to be vented outside while fresh air is brought into the mine. In above-ground quarries, dust collectors help control nuisance dust thereby being a good neighbor and employer. Dust collectors can also help recover valuable raw materials.

Aerodyne manufactures industrial dust collectors that are well suited for mining and quarry applications. Both the GPC and the SplitStream are available in horizontal configurations which is ideal for the limited space found in mines.

The GPC Cyclone has a removal rate of 99% of 20 micron dust. The compact design is perfect for low profile areas that are found in mines. Horizontal designs can be used to replace existing ductwork for retrofits. It is an ideal choice for being used as pre-filter to baghouses and cartridge collectors to increase bag/cartridge life and increase existing system efficiencies.

The SplitStream Cyclone has a removal rate of approximately 100% of 10 micron dust, 90% of 2 micron dust. The secondary airflow minimizes the erosion of the collector walls, which reduces wear on the dust collector. The vertical and horizontal configurations allow for efficient dust collection in confined spaces. The horizontal design can even replace existing ductwork.

Aerodyne also offers a variety of material handling valves that are rugged enough to operate in the harsh mining or quarry conditions.

The Vacu-Valve trickle valve system is an economical alternative to Rotary valves and is used in many mines and quarries. It requires no lubrication, power supply, or controls. There are a variety of duckbill sleeve options to suit any application. Requires vacuum above (-16″ W.C. max).

The GatorGate Double Dump Valve is designed to pass bulky material that would normally jam rotary valves. The double gate is designed so the airlock is maintained. Easy accessible access doors allow for speedy maintenance.

Aerodyne’s Knife Gate Valve is ideal for hoppers, bins, and storage vessels. There are manual and pneumatic designs available in 8″, 10″, and 12″ sizes.

Equipment Gallery

See more Aerodyne dust collection applications.