Grinding and Particle Reduction Cyclones

Particle size reduction is often done in grinding equipment. Grinders include roller mills, ball mills, and hammer mills which use shear and impact to reduce the size of the particles. A crusher is also used for particle size reduction (compression). All of them use high speed action to cause the material to break into smaller particles. Those particles are energized leaving the grinding equipment. The material can either be pneumatically transported away or it can be collected at the outlet. If pneumatically transferred away, there will be high concentrations of particles which could cause operating issues with cartridge collectors and baghouses at the collection point. And if it is collected directly from the machine, small particulate can escape the collection equipment causing dust clouds and product loss. A hood is usually used to minimize the dust escaping. This dust must be collected so that it doesn’t cause issues in the facility (both safety and environmental) but most importantly because this dust is often times the product or intermediate that is being produced. This means the grinders will require dust collector systems to be installed.

The grinder’s dust is often produced in very high concentrations. These high concentrations can cause operational issues in filters such as the bags and cartridges used in baghouses and cartridge collectors. A good way to prevent these issues is by installing a cyclone pre-filter between the grinder and the filters. The cyclone uses centrifugal motion to remove the majority of the materials before the material reaches the filters. This significantly decreases the dust loading going to the filters, allowing efficiently operation while collecting the very fine dust that got through the cyclone.

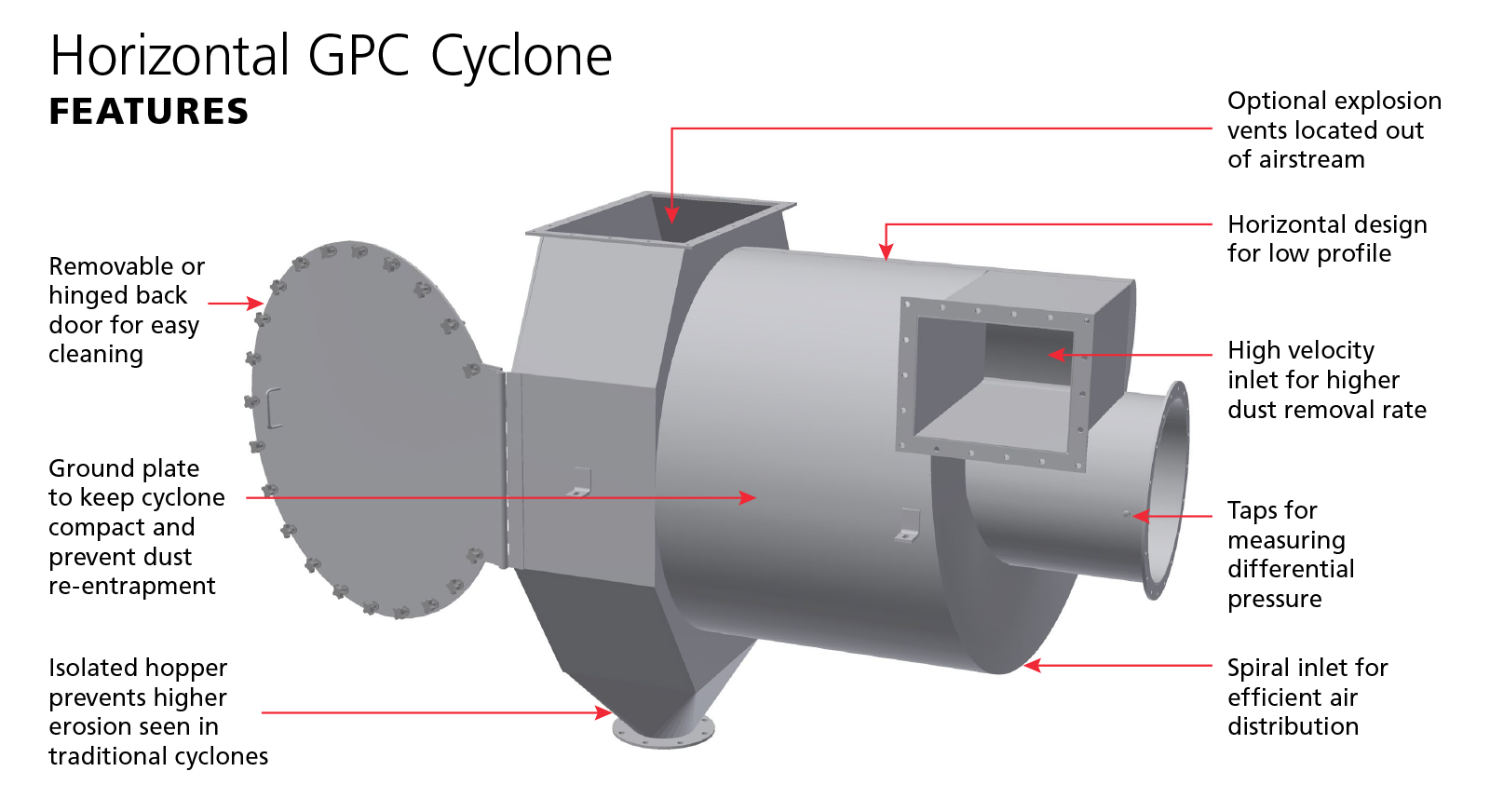

Benefits of the Aerodyne Horizontal GPC Cyclone

- Horizontal design allows it to be located in areas where a traditional cyclone won’t easily fit. Lower airflow units could even be portable.

- Horizontal design allows the back plate to open, allowing cleaning of the internals without dismantling the cyclone and the ductwork.

- Horizontal design allows explosion vents to be installed out of the high velocity air chamber, therefore minimizing wear by high-speed dust.

Issues in Filters Caused by High Dust Loading

- Heavy loading can plug up bags and pleated filters, preventing airflow and lowering material throughput or even plugging of the grinders.

- Higher dust loading causes filters to plug up faster, thereby requiring replacement more often.

- High dust loading can cause holes to develop in the filters, allowing material past the filters and out of the dust collection system.

Benefits of Cyclone Dust Collectors

- A cyclone collector removes the larger dust particles. It can often get 90+% removal of material on the 1st pass. This can significantly lower the dust loading on the filters.

- Cyclones don’t have filters so a properly designed cyclone won’t allow dust to buildup inside, thereby contaminating the material collected like a filter will.

- Grinders operating at high temperatures or that could produce sparks could cause the filters to catch fire and/or possibly explode. A cyclone pre-filter will give time for the sparks to cool and with the removal of material from the airstream help cool the system before it reaches the filters.