Aerodyne SplitStream™ Dust Collector Installation Options

The Aerodyne SplitStream Dust Collector utilizes a powerful secondary air stream to increase efficiency, protect against abrasive wear, and allow for horizontal installation. Three options are available for obtaining the secondary air stream supply for this high-efficiency dust collector. These three installation options give the SplitStream unmatched flexibility for a wide range of dust collection application conditions.

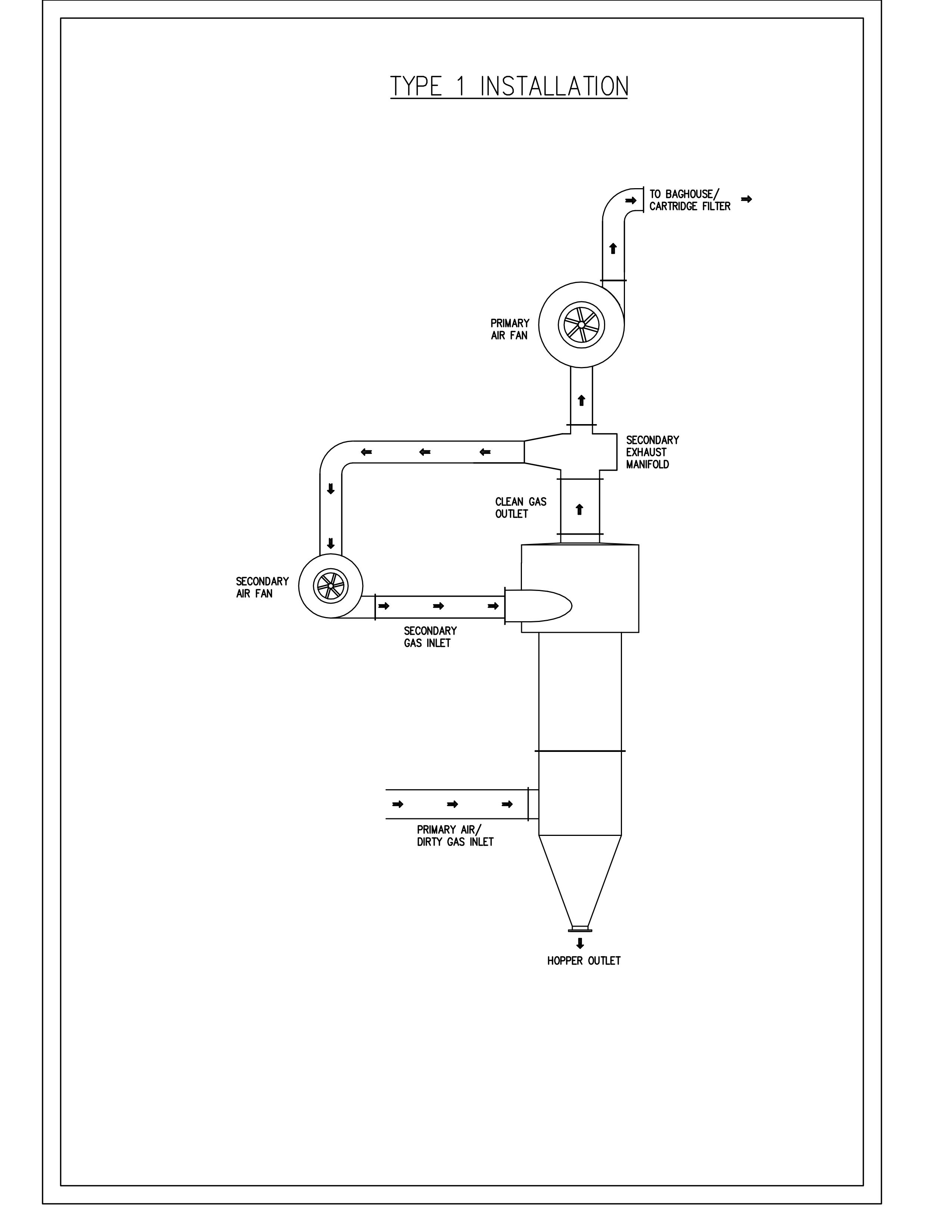

Type 1 Installation

The secondary gas stream is drawn from the clean exhaust gases of the collector and circulated in a closed loop through the secondary air circuit of the dust collector. This is accomplished through the use of a secondary exhaust manifold which directs air back to the secondary gas circuit while allowing the remaining gas volume to exhaust from the system. The primary benefit of this installation is the inlet and outlet gas volumes are not affected, making the dust collector’s outlet gas volume equal to the primary gas inlet volume. With this arrangement, some carryover dust that has been exhausted is returned to the dust collector for another opportunity to be collected. In the Type 1 Installation, some particulate enters the secondary air stream and the collector’s nozzles should be periodically inspected for dust build-up or clogging.

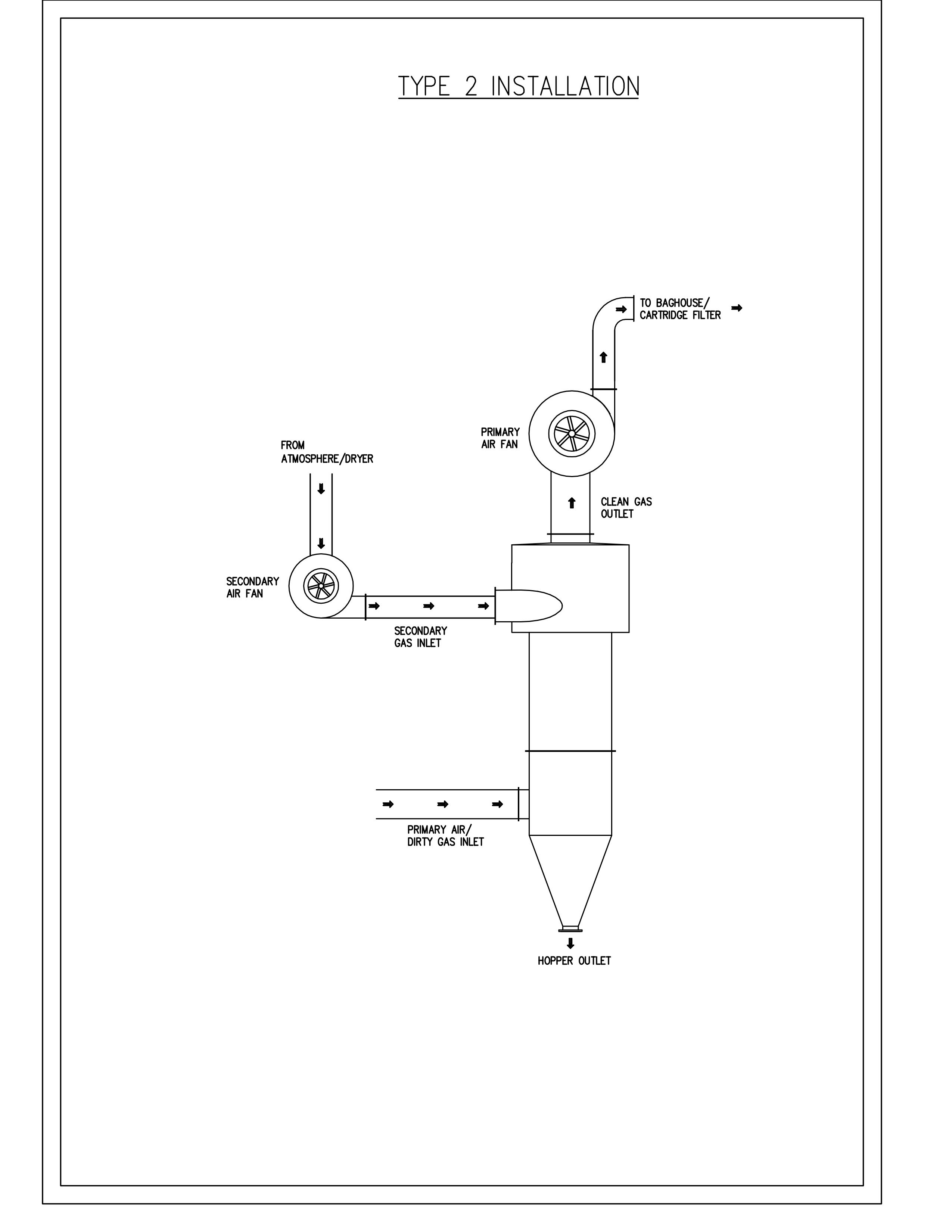

Type 2 Installation

In this arrangement, secondary gas is taken from the atmosphere or some other designated source. The exhaust volume for the Type 2 Installation is the sum of the primary inlet and the secondary inlet gases. This arrangement is the standard and most common arrangement for most dust collection applications. Heating, cooling, or drying can be accomplished at the same time as dust collection because the secondary air stream can be drawn from a variety of sources. Hot air from a dryer or cool air from the atmosphere can be utilized in this setup. Another benefit to the Type 2 Installation is the reduced maintenance on the dust collector’s nozzles. By adding only “clean” air to the secondary air circuit the dust collector’s nozzles remain free from dust buildup.

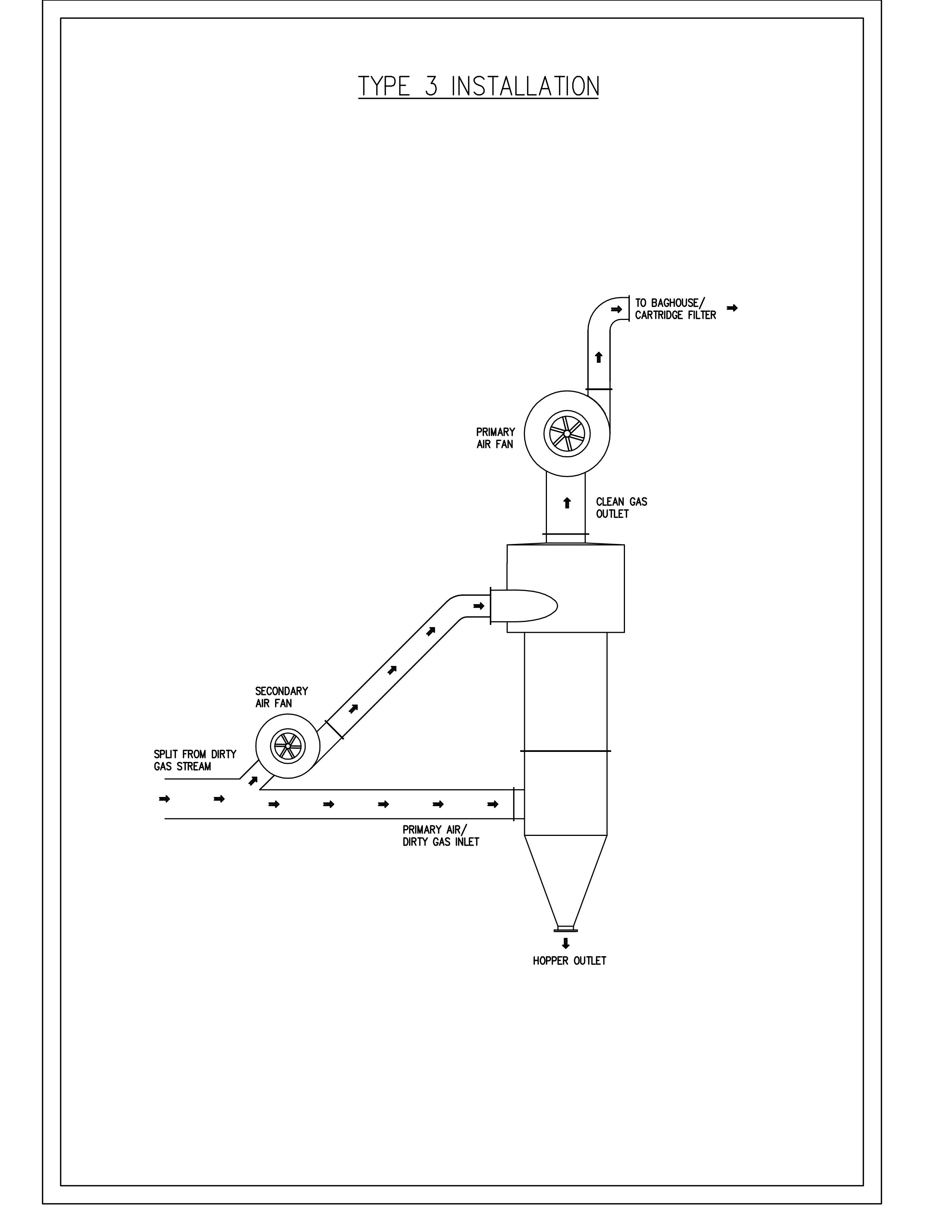

Type 3 Installation

This installation method is primarily used to increase process capacity. Secondary gas is obtained by splitting the dust-laden gas stream between the primary and secondary air circuits of the dust collector. The process capacity increases by the amount entering the secondary air circuit, however, the collection efficiency is somewhat reduced. If dust loading is extremely high, plugging of the collector’s nozzles can occur. Additionally, this arrangement requires that at least the secondary fan operate on dust-laden air, which can cause potential problems with fan imbalance. While the least common of SplitStream™ configurations, the ability to increase process capacities makes the Type 3 Installation a valuable option.

The unique dual-air stream design of the Aerodyne SplitStream Dust Collector not only provides exceptionally high dust collection efficiency but also provides a range of installation options not possible with standard cyclone dust collectors.

See additional Articles from Aerodyne.