Many mining and industrial applications for dust collection require equipment able to fit in tight, compact areas, a challenge for many traditional dust collection cyclones. Aerodyne, the industry's leader in industrial dust collection and material handling valves, has developed a series of compact high-efficiency solutions to industries with demanding dust collection applications, and it has developed an infographic to highlight the space-saving capabilities of its cyclone dust collection solutions.

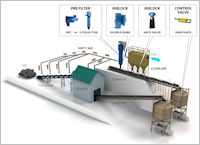

Understanding the full process of dust collection systems in a mining or quarry application can be overwhelming. There are various touch points across the process that help make the whole system complete. A missing piece leaves room for error and lowers the overall efficiency.

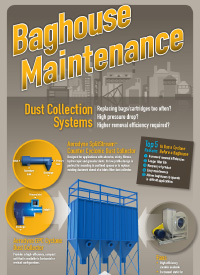

What is Your Dust Collection Cost After Baghouse Maintenance?

Baghouse maintenance expenses accumulate quickly. Whether the cost is replacing bags, machine downtime or maintenance wages, a cyclone dust collector can dramatically lower the expense. Placing a cyclone dust collector in front of a baghouse dust collector allows operation in difficult applications like sticky or abrasive dusts. It also increases the dust collection removal efficiencies providing the baghouse better product recovery, a longer fabric filter baghouse life and reduced baghouse maintenance.

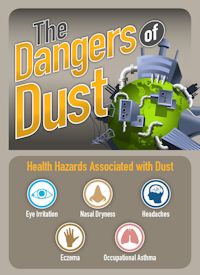

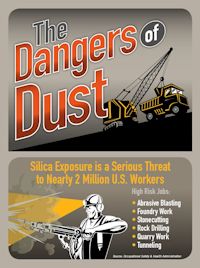

The dangers of dust often remain unseen like the small particles themselves. Not only are health hazards associated with dust but also quality control issues. Many of these uncollected dust particles are explosive and can create a safety hazard. In fact, there have been 350 explosions from dust since 1980. Solve these potential problems before they begin with Aerodyne's industrial dust collection systems.

Did you know that a dust explosion occurs every week? Furthermore, nearly 2 million US employees are exposed to silica as a result of insufficient dust control in the workplace. Industrial dust control is used to prevent these dangerous and deadly situations. Aerodyne's dust collectors provide explosion proof industrial dust control. The dust collection systems remove particulate as a form of pollution control and particulate reclamation.