|

|

|

August 2014 | Industrial Dust Collection Chronicle

|

- Vacu-Valve Offers Cost-Effective Solution for Mining Company

- New Animated Demo Highlights How Dust Collection Works in Mines and Quarries

- From The Blog – Dust Collection System Keeps Communication Rolling

- Aerodyne's New Dust Collector Facts Book – The Industry's Leading Informational Guide

- Infographic: What is Your Dust Collection Cost After Baghouse Maintenance?

- White Paper: Top Benefits Your Application Receives When Using a Cyclone in Front of a Baghouse/Cartridge Collector

- About Aerodyne

|

|

Limestone Quarry Achieves Major Savings by Replacing Rotary Airlocks with Trickle Valves

|

|

A state–of–the–art limestone mining facility located in Sandusky, Ohio was experiencing problems with its rotary airlock valves. Wagner Quarries Company has been in continuous operation since 1912, blasting limestone in the leading area in the state of Ohio for nine generations. Large baghouse dust collectors are used on–site to capture massive amounts of airborne dust derived from the blasting, drilling, crushing, loading, and hauling operations required to extract this valuable resource.

Read this complete article.

|

|

|

|

|

Aerodyne Video Shows How High-Efficiency Dust Collection Works in Mines and Quarries

|

|

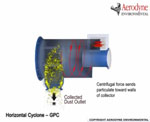

Our new animation demonstrates how industrial dust collectors operate in a mining or quarry application. In the demo, the Ground-Plate (GPC) Cyclonic Dust Collector and the Vacu-Valve trickle valve system show how industrial dust collection systems manage the dirty air that is created in mining applications.

View demo.

|

|

|

|

|

From the Blog: Dust Collection System Keeps Communication Rolling

|

|

A company in FL that specializes in manufacturing command and communication vehicles was in need of dust collection system. The facility was going to be purchasing a CNC router machine from its sister company and it would require a dust collector to work with it. The CNC would be producing metal dust and the unit would require 1300 CFM. The company reached out to Aerodyne for suggestions on products that would fit its needs.

Read this complete article.

|

|

|

|

Free Resources: Dust Collection Facts Book

|

|

|

|

Product Highlights

SplitStream™ Counter Cyclonic

Dust Collector

|

Vacu-Valve® - Trickle Valve System |

Ground-Plate (GPC) Cyclone Dust Collector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

About Aerodyne Environmental - Aerodyne Environmental has been specializing in solving dry material handling problems for more than 60 years through such products as high-efficiency cyclone dust collectors and low-cost,

low-maintenance, material-handling valves. Aerodyne operates under the corporate motto "Clean Our World®", addressing material handling challenges through innovation, customer commitment,

and environmental stewardship.

|

|

|

{VR_SOCIAL_SHARING}

|

|

|

|

|